Inventory Management

- Inventory (stock)- materials and goods required to allow for the production and supply of products to the customer

MAIN FORMS OF INVENTORY HELD BY A MANUFACTURING BUSINESS

- Raw materials and components

- These will have been purchased from outside suppliers and are held in storage until they are used in the production process

- These inventories can be drawn upon at any time and allow the firm to meet increases in demand by increasing the rate of production quickly

- Work in progress

- At any one time the production process will be converting raw materials and components into finished goods- during this process there will be ‘work in progress’ and for some firms, such as building and construction businesses, this will be the main form of inventories held

- The value of work in progress depends not only on the length of time needed to complete production but also on the method of production used- batch production tends to have high work-in-progress levels.

- Finished goods

- Having been through the complete production process, goods may then be held in storage until sold and despatched to the customer

- These inventories can be displayed to potential customers and increase the chances of sales

- They are also held to cope with sudden, unpredicted increases in demand so that customers can be satisfied without delay

- Firms will also stockpile completed goods to meet anticipated increases in demand as with seasonal goods or products, such as toys at festival times

INVENTORY MANAGEMENT

- Without effective inventory management several serious problems could arise for the firm:

- There might be insufficient inventories to meet unforeseen changes in demand

- Out-of-date inventories might be held if an appropriate rotation system is not used, for example for fresh foods or for fast-changing technological products, such as tablet computers

- Inventory wastage might occur due to mishandling or incorrect storage conditions.

- Very high inventory levels may result in excessive storage costs and a high opportunity cost for the capital tied up

- Poor management of the supplies purchasing function can result in late deliveries, low discounts from suppliers or too large a delivery for the warehouse to cope with

INVENTORY-HOLDING COSTS

- Opportunity cost

- Working capital tied up in goods in storage could be put to another use- it might be used to pay off loans, buy new equipment or pay off suppliers early to gain an early-payment discount

- The capital could be left in the bank to earn interest

- The most favourable alternative use of the capital tied up in inventories is called its ‘opportunity cost’- the higher the value of inventories held, and the more capital used to finance them, then the greater will be this opportunity cost.

- During periods of high interest rates, the opportunity cost of inventory holding increases.

- Storage costs

- Inventories have to be held in secure warehouses. They often require special conditions, such as refrigeration.

- Employees will be needed to guard and transport the goods. Insurance of inventories is recommended in case they are stolen or damaged by, for example, fire or flood.

- If finance has to be borrowed to buy the goods held in storage, then this will incur interest charges. These are all costs that add to the firm’s overheads.

- Lower inventory levels are likely to reduce these costs significantly.

- Risk of wastage and obsolescence

- If inventories are not used or sold as rapidly as expected, then there is an increasing danger of goods deteriorating or becoming outdated. This will lower the value of such inventories.

- Goods often become damaged while held in storage or while being moved – they can then be sold only for a much lower price.

COSTS OF NOT HOLDING ENOUGH INVENTORIES

- Lost sales

- If a firm is unable to supply customers from goods held in storage, then sales could be lost to firms that hold higher inventory levels. This might lead to future lost orders too. In purchasing contracts between businesses, it is common for there to be a penalty-payment clause requiring the supplier to pay compensation if delivery dates cannot be met on time.

- Idle production resources

- If inventories of raw materials and components run out, then production will have to stop. This will leave expensive equipment idle and labour with nothing to do. The costs of lost output and wasted resources could be considerable.

- Special orders could be expensive

- If an urgent order is given to a supplier to deliver additional materials due to shortages, then extra costs might be incurred in administration of the order and in special delivery charges.

- Small order quantities

- Keeping low inventory levels may mean only ordering goods and supplies in small quantities. The larger the size of each delivery, the higher will be the average level of inventories held. By ordering in small quantities, the firm may lose out on bulk discounts, and transport costs could be higher as so many more deliveries have to be made.

- Economic order quantity- the optimum or least-cost quantity of stock re-order taking into account delivery costs and stock-holding costs

CONTROLLING INVENTORY LEVELS- A GRAPHICAL APPROACH

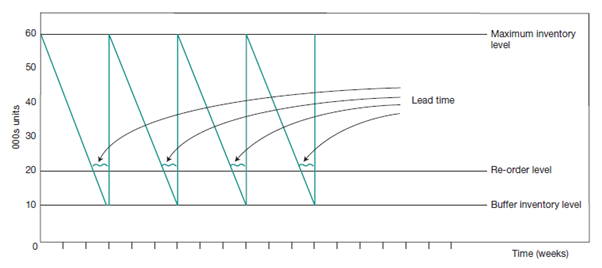

- Inventory-control charts or graphs are widely used to monitor a firm’s inventory position. These charts record, over time, the numbers of goods held, inventory deliveries, buffer levels and maximum inventory.

- They aid an inventory manager to determine the appropriate order time and order quantity as well as allowing an analysis of what would happen to inventory levels if an unusual event occurred, such as a competitor operating a really successful promotion campaign

- Key features of an inventory-control chart:

- Buffer inventories- the minimum inventory level that should be held to ensure that production could still take place should a delay in delivery occur or should production rates increase

- Maximum inventory level- the maximum amount of inventory that can be store in a business’ warehouse; this may be limited by space or by the financial costs of holding even higher inventories

- Re-order quantity- the number of units ordered each time, and it is influenced by the economic order quantity concept

- Lead time- the normal time taken between ordering new stocks and their delivery; the longer this period of time, then the higher will have to be the reorder stock level; the less reliable suppliers are, the greater the buffer stock level might have to be

- Re-order stock level- the level of stocks that will trigger a new order to be sent to the supplier

JUST-IN-TIME (JIT) INVENTORY CONTROL

- Just-in-time- this inventory-control method aims to avoid holding inventories by requiring supplies to arrive just as they are needed in production and completed products are produced to order

- Important requirements for a business to use JIT:

- Relationships with suppliers have to be excellent

- Suppliers must be prepared and able to supply fresh supplies at very short notice – short lead time

- Suppliers have to see that being reliable and consistent is of great long-term benefit to them as well as the business adopting JIT

- Often, this means that a business will have only one, or at most two, suppliers for each component so that a relationship of mutual benefit can be built up

- Production staff must be multiskilled and prepared to change jobs at short notice

- Each worker must be able to switch to making different items at very short notice so that no excess supplies of any one product will be made

- Equipment and machinery must be flexible

- Old-fashioned manufacturing equipment tended to be designed to produce one range of very similar products. It might have taken days to adapt it to making other types of products. This equipment would be most unsuitable for JIT-based systems.

- Modern, computer-controlled equipment is much more flexible and adaptable – often able to be changed with just a different software program. In this way, very small batches of each item can be produced, which keeps stock levels to an absolute minimum.

- However, such equipment is expensive and, as a result, JIT may not be so appropriate for small or underfinanced firms.

- Accurate demand forecasts will make JIT a much more successful policy

- If it is very difficult for a firm to predict likely future sales levels, then keeping zero inventories of materials, parts and finished goods could be a very risky strategy.

- Demand forecasts can be converted into production schedules that allow calculation of the precise number of components of each type needed over a certain time period.

- The latest IT equipment will allow JIT to be more successful

- Accurate data-based records of sales, sales trends, reorder levels and so on will allow very low or zero inventories to be held.

- Similarly, if contact with suppliers can be set up with the latest electronic data exchanges, then automatic and immediate ordering can take place, when it is recorded that more components will shortly be required.

- Excellent employee-employer relationships are essential for JIT to operate smoothly

- Any industrial-relations problem could lead to a break in supplies and the entire production system could grind to a halt.

- Quality must be everyone’s priority

- As there are no spare inventories to fall back on, it is essential that each component and product must be right first time. Any poor-quality goods that cannot be used will mean that a customer will not receive goods on time

- Relationships with suppliers have to be excellent

- Advantages

- Capital invested in inventory is reduced and the opportunity cost of inventory holding is reduced.

- Costs of storage and inventory holding are reduced. Space released from the holding of inventories can be used for a more productive purpose.

- Much less chance of inventories becoming outdated or obsolescent. Fewer goods held in storage also reduces the risk of damage or wastage.

- The greater flexibility that the system demands leads to quicker response times to changes in consumer demand or tastes.

- The multiskilled and adaptable staff required for JIT to work may gain from improved motivation.

- Disadvantages

- Any failure to receive supplies of materials or components in time caused by, for example, a strike at the supplier’s factory, transport problems or IT failure will lead to expensive production delays.

- Delivery costs will increase as frequent small deliveries are an essential feature of JIT.

- Order-administration costs may rise because so many small orders need to be processed.

- There could a reduction in the bulk discounts offered by suppliers because each order is likely to be very small.

- The reputation of the business depends significantly on outside factors such as the reliability of supplying firms.

- Evaluation

- JIT requires employees to be much more accountable for their performance and suppliers to be very reliable as any failure to meet targets will lead to production stopping.

- There is no surplus or buff er in the JIT system to cover up for inefficient workers, inflexible people and equipment, unreliable suppliers, or poor production planning.

- JIT may not be suitable for all firms at all times:

- There may be limits to the application of JIT if the costs resulting from production being halted when supplies do not arrive far exceed the costs of holding buffer inventories of key components.

- Small firms could argue that the expensive IT systems needed to operate JIT effectively cannot be justified by the potential cost savings.

- Rising global inflation makes holding inventories of raw materials more beneficial as it may be cheaper to buy a large quantity now than smaller quantities in the future when prices have risen. Similarly, higher oil prices will make frequent and small deliveries of materials and components more expensive.